for Efficient Mixing in Diverse Industries

A Ribbon Blender is a versatile and cost-effective mixing machine widely used in various industries, including chemical, pharmaceutical, food, agricultural, nutraceuticals, and polymers. It consists of a horizontal trough with a central shaft and a helical ribbon agitator, providing efficient and thorough blending of dry solids. Here are the salient features and characteristics of a Ribbon Blender:

Send Inquiry

cGMP Design: The Ribbon Blender is designed in compliance with cGMP (Current Good Manufacturing Practices), ensuring adherence to high-quality standards in pharmaceutical and related industries.

Material Construction: Contact parts of the blender are constructed from AISI 316 stainless steel, ensuring corrosion resistance and compliance with industry standards. Non-contact parts are made of AISI 304 stainless steel.

Fully Automatic Operation: The blender operates fully automatically, controlled by a Programmable Logic Controller (PLC). This feature enhances operational control and efficiency in the blending process.

Flame-Proof Construction: Flame-proof construction can be provided upon request, ensuring safety in environments where explosion-proof equipment is required.

Adaptability to Batch or Continuous Mixing: The Ribbon Blender is adaptable to both batch and continuous mixing operations, providing flexibility in manufacturing processes.

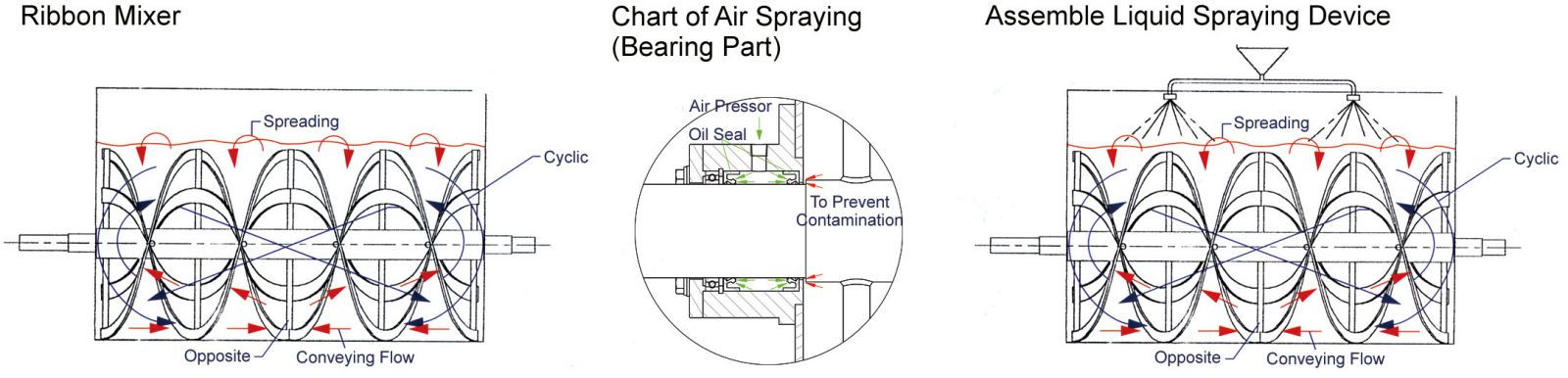

Ribbon Design: The ribbon design, including cross-section, pitch, and close clearances between the outer ribbon and shell, is adjustable to accommodate various materials ranging from low-density finely divided materials to fibrous and sticky materials.

Heating or Cooling Jacket: The blender can be equipped with a heating or cooling jacket as per process requirements, allowing for precise temperature control during the blending process.

Choppers: Choppers, available as a Delumper or Fine Grinder, can be integrated into the blender for additional material processing capabilities.

Hinged Cover and Dependable Discharge Outlet: The blender features a hinged cover for easy access and a dependable discharge outlet. Discharge is controlled manually with a lever or hand wheel-operated slide gate valve.

Optional Scale Hoppers: Scale hoppers are available as optional features, providing additional functionality for specific material handling needs.

Fast and Easy Cleaning: The design facilitates fast and easy cleaning. The entire ribbon assembly is removable as a unit, streamlining maintenance processes.

Shaft Seal: The blender is equipped with a shaft seal featuring three rows of packing, housed in a standard gland follower stuffing box. Purged and lubricated seals, as well as mechanical seals, are also available.

CIP System: A Clean-In-Place (CIP) system can be provided with a pump as an optional feature, ensuring convenient and efficient cleaning of the blender.

CGMP Model with Documentation: The CGMP model comes with comprehensive documentation, including Installation Qualification (IQ), Design Qualification (DQ), Performance Qualification (PQ), and Operational Qualification (OQ), providing a complete quality assurance package.

The Ribbon Blender's efficient and adaptable design makes it a valuable asset in industries where precise blending of dry solids is essential. Its ability to handle a wide range of materials, along with advanced features and compliance with industry standards, makes it suitable for diverse manufacturing processes.

| Sr No | Model | Gross Capacity (L) | Working Capacity (L) | RPM | Main Motor (H.P.) |

| 1 | RIB-150 | 150 L | 100 L | 15/30 | 3 - 5 HP |

| 2 | RIB-500 | 500 L | 325 L | 15/30 | 5 - 5 HP |

| 3 | RIB-1000 | 1000 L | 650 L | 15/30 | 7.5 - 10 HP |

| 4 | RIB-2000 | 2000 L | 1300 L | 15/30 | 10 - 15 HP |

| 5 | RIB-3000 | 3000 L | 2000 L | 15/30 | 20 - 25 HP |

| 6 | RIB-4000 | 4000 L | 2600 L | 15/30 | 25 - 30 HP |

| 7 | RIB-5000 | 5000 L | 3250 L | 15/30 | 30 - 40 HP |

| 8 | RIB-7500 | 7500 L | 5000 L | 15/30 | 40 - 50 HP |

| 9 | RIB-10000 | 10000 L | 6500 L | 15/30 | 60 - 75 HP |