Optimal Drying Solution

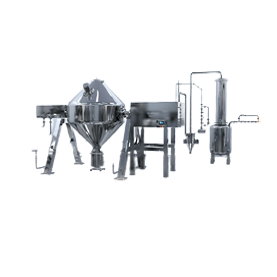

The RotoCone Vacuum Dryer, also known as Roto Cone Vacuum Dryer (RCVD), proves ideal for drying materials sensitive to high temperatures, easily oxidized substances, volatile compounds, and those with irritant or poisonous properties. This advanced technology operates under vacuum conditions, promoting enhanced drying efficiency, low-temperature operation, and solvent recovery in compliance with cGMP standards.

Send Inquiry

Enhanced Drying EfficiencyI: mproved technology for efficient drying and solvent recovery.

Low-Temperature Operation: Operates at lower temperatures under vacuum conditions.

Lump Breakers: Equipped with lump breakers to reduce large lumps and ensure a lump-free product.

Unsurprising and Repeatable Results: Vacuum drying provides consistent and repeatable outcomes.

Safe for Friable Goods: Ideal for delicate and friable solids due to low-speed operation.

Low Cross Contamination: Minimal surface area and simple design reduce cross-contamination.

Easy Inspection and Cleaning: Simple interior design facilitates easy inspection and cleaning.

Corrosion Prevention: Suitable for preventing corrosion with an optional nitrogen purging system.

CGMP Compliance: Adheres to Current Good Manufacturing Practices.

Material Construction: Contact parts made of AISI 316, non-contact parts made of AISI 304.

Flame-Proof Construction: Optional flame-proof construction for added safety.

FDA Compliance: In compliance with FDA regulations.

Rounded Internals: Ensures smooth internal operations.

Validation Documents: DQ, IQ/OQ, FAT/SAT provided for validation purposes.

Capacity: 5 - 5000 Ltrs.

Material of Construction: SS304/ SS316/ SS316L/ Hastelloy.

Optional Accessories: Lump breaker provision, nitrogen purging arrangement, various coatings for wetted parts (HALAR/ ETFE/ PVDF/ PFA - Food Grade), direct drive to avoid greasing of the gear.

The Roto Cone Vacuum Dryer stands as a reliable and efficient solution for diverse drying needs, ensuring product quality, safety, and compliance with industry standards.

| Sr No | Model | Gross Capacity in Liters |

Working Capacity in Liters |

Working Capacity in Kg |

RPM | MAIN MOTOR H.P. |

| 1 | RCVD-25 | 25 L | 18 L | 9 Kg | 20 | 2.0 HP |

| 2 | RCVD-50 | 50 L | 35 L | 18 Kg | 20 | 2.0 HP |

| 3 | RCVD-100 | 100 L | 70 L | 35 Kg | 20 | 3.0 HP |

| 4 | RCVD-300 | 300 L | 210 L | 105 Kg | 20 | 3.0 HP |

| 5 | RCVD-500 | 500 L | 350 L | 175 Kg | 2-10 | 5.0 HP |

| 6 | RCVD-750 | 600 L | 420 L | 210 Kg | 2-10 | 5.0 HP |

| 7 | RCVD-1000 | 1000 L | 700 L | 350 Kg | 2-10 | 7.5 HP |

| 8 | RCVD-2000 | 2000 L | 1400 L | 700 Kg | 2-10 | 10.0 HP |

| 9 | RCVD-3000 | 3000 L | 2100 L | 1050 Kg | 2-10 | 12.0 HP |

| 10 | RCVD-5000 | 5000 L | 3500 L | 1750 Kg | 2-10 | 15.0 HP |